The present material research – conducted in collaboration with Arup in London – aims at optimizing a stressed skin system by using a perforation pattern derived from the relevant stress analyses of the structure.

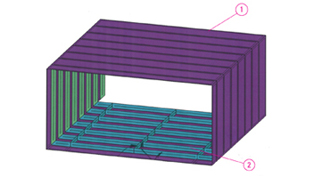

A 8-meter long open box structure – acting as a bridge supported at the two open ends – is built using 15mm (5/8″) solid aluminum plates welded to a frame, forming prefabricated panels that are shipped on site and bolted in place.

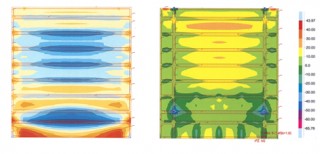

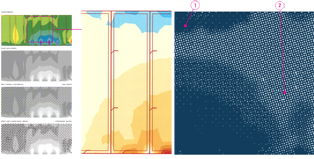

Stress plot of ceiling (1) and floor (2)

The structure is evaluated by running stress analysis of the floor, ceiling and 2 side walls.

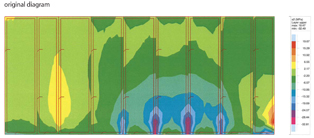

Stress plot of side wall

Each stress plot is then converted into a gray gradient indicating discreet load values.

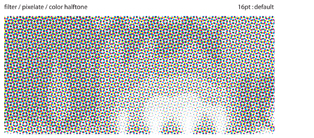

Progressive filters are applied to the gradient, generating a perforation pattern with holes of different density, grain and scale.

The perforation pattern is transformed into a vector drawing and used by a water jet cutter to manufacture each plate.

The varying parameters in the perforation pattern reflect the stress levels at each point of the plate, removing material where load analysis indicates a surplus in strength, and reducing the overall weight of the bridge, thus making the structure inherently more efficient.

Pattern type 1

Pattern type 2

Interestingly, the type of pattern has structural repercussions as well: it is not only the amount of material removed, but also the particular shape of the openings that determines the resulting strength of the plate.

The results are applied to the entrance of the Xicui Entertainment Center in Beijing.